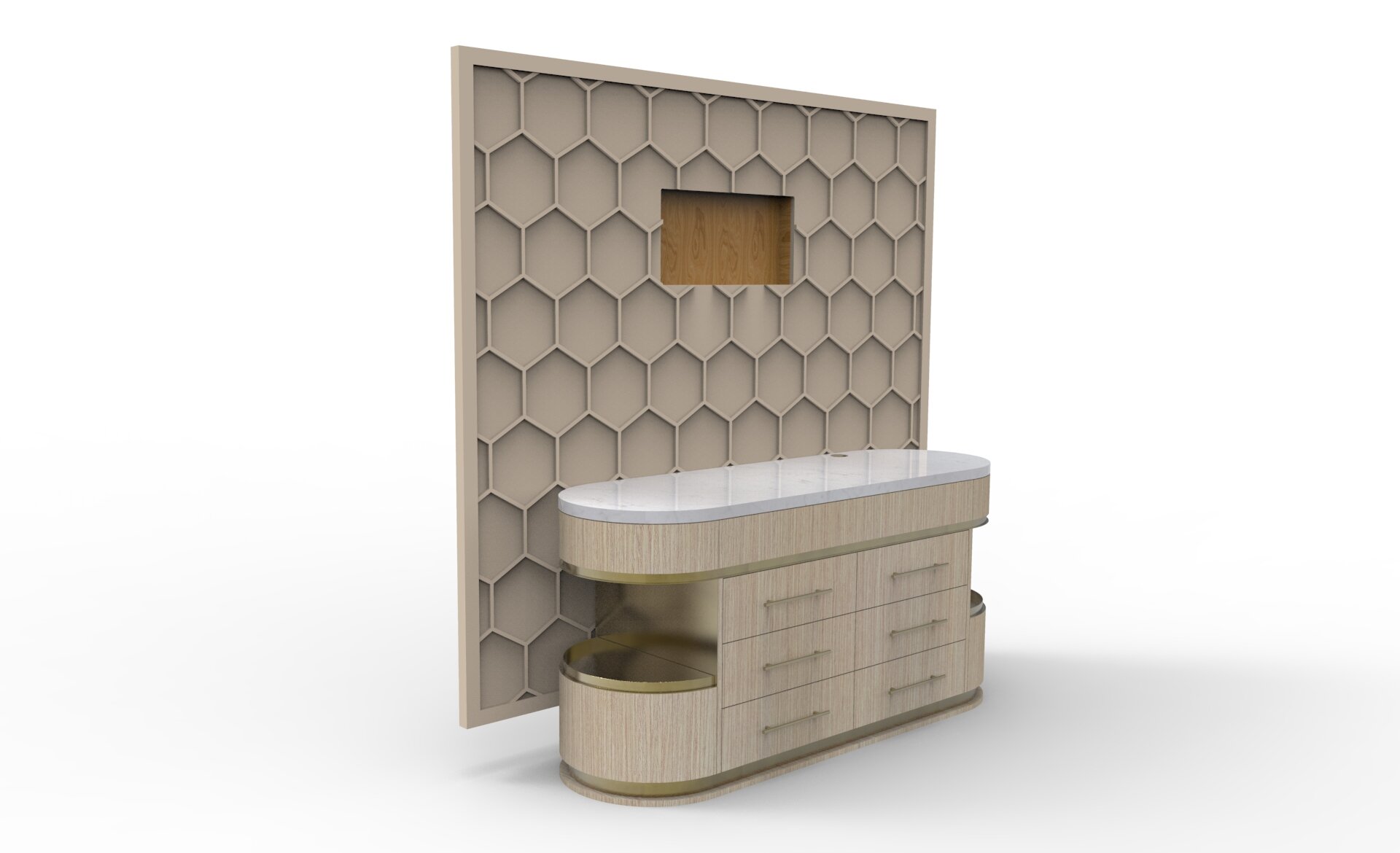

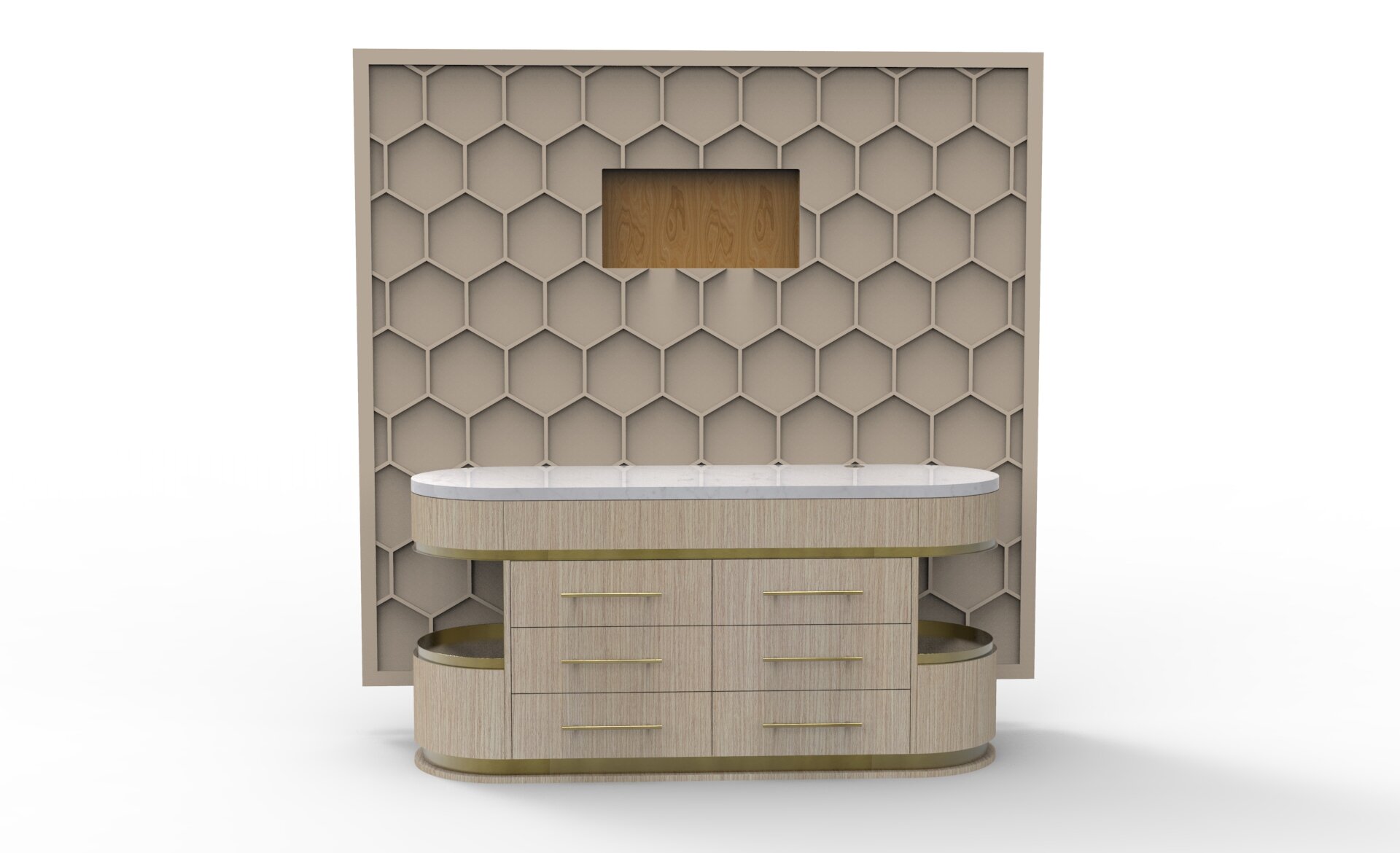

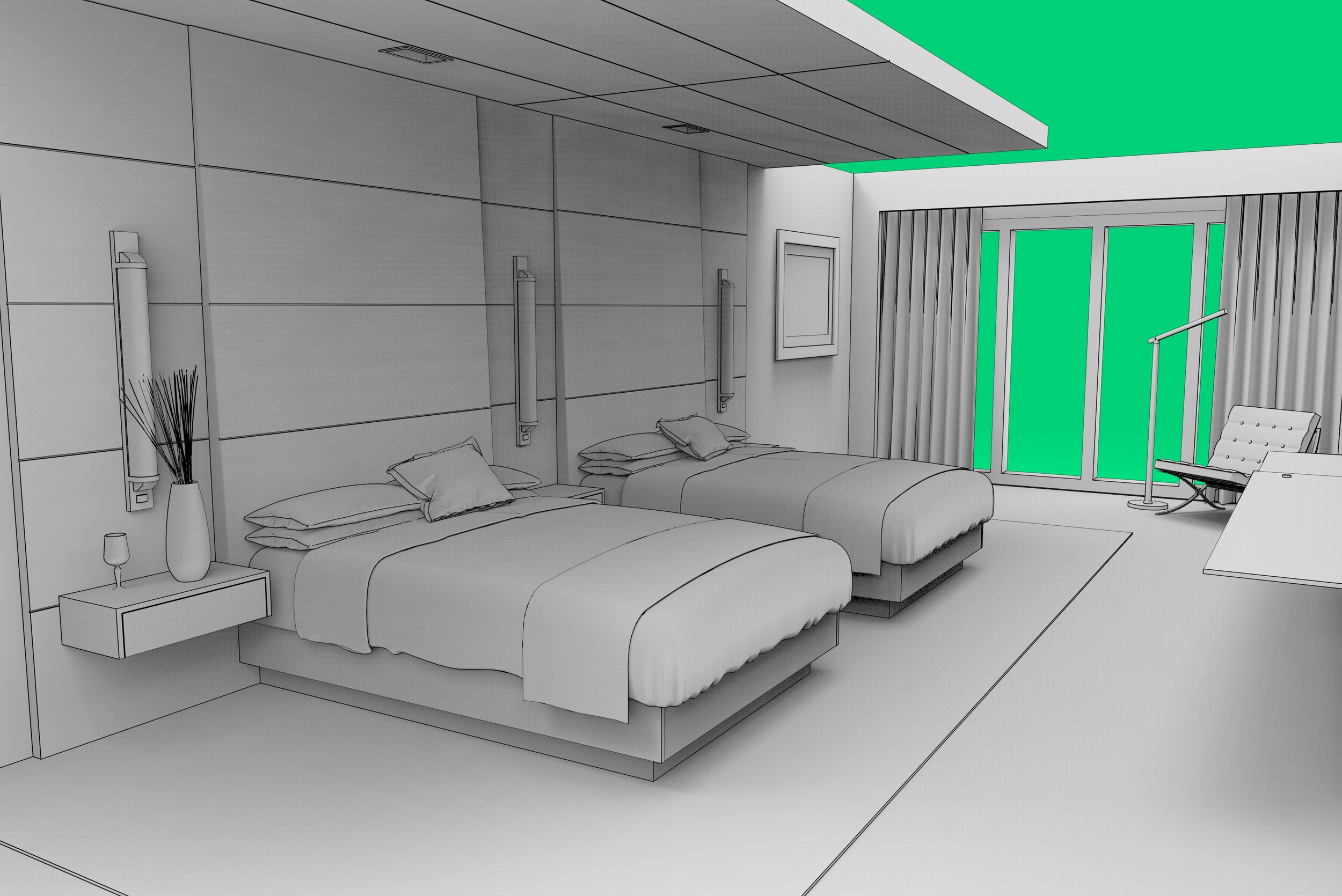

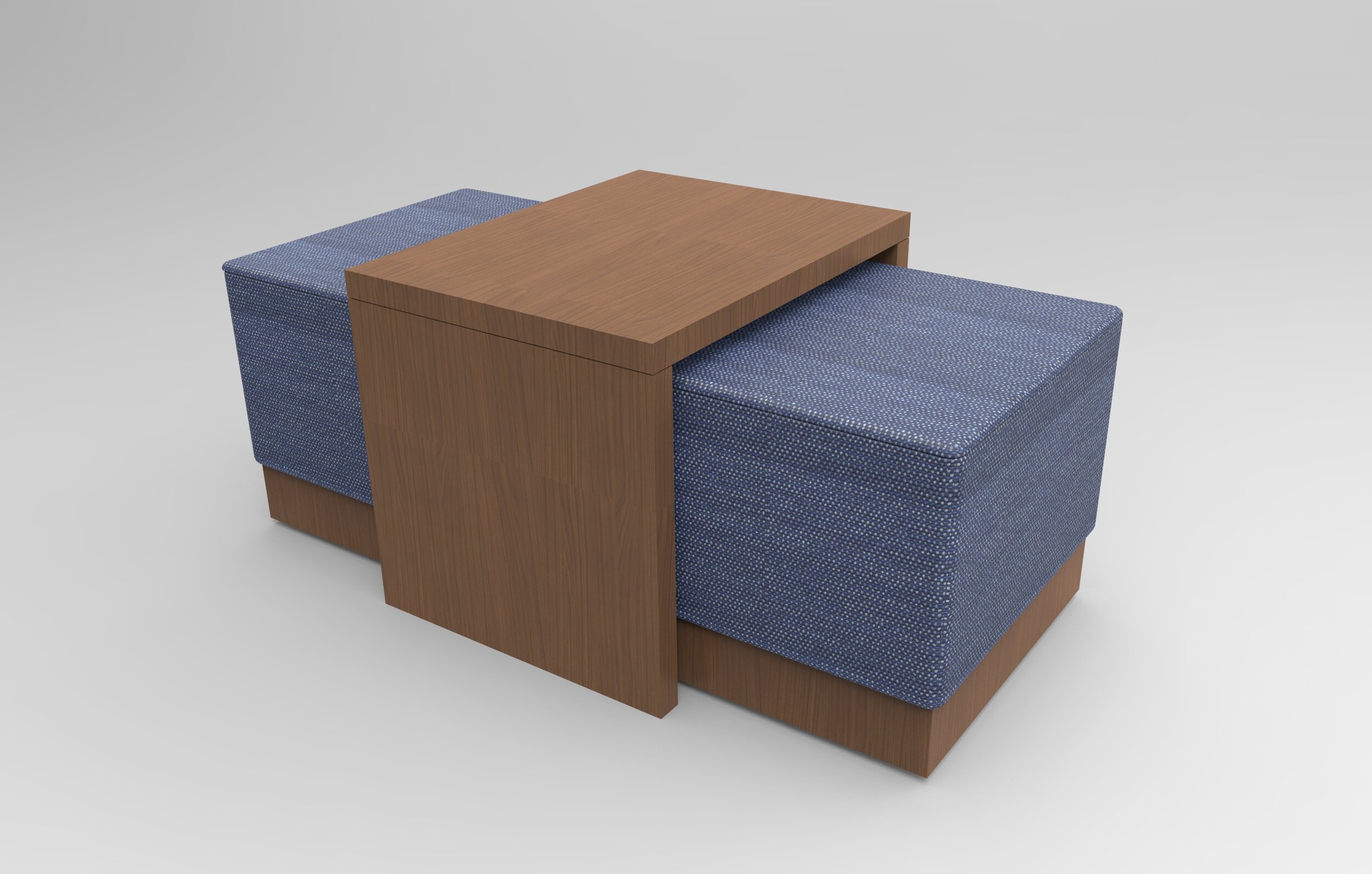

Rendering

WHAT DO YOU NEED TO GET A RENDERING?

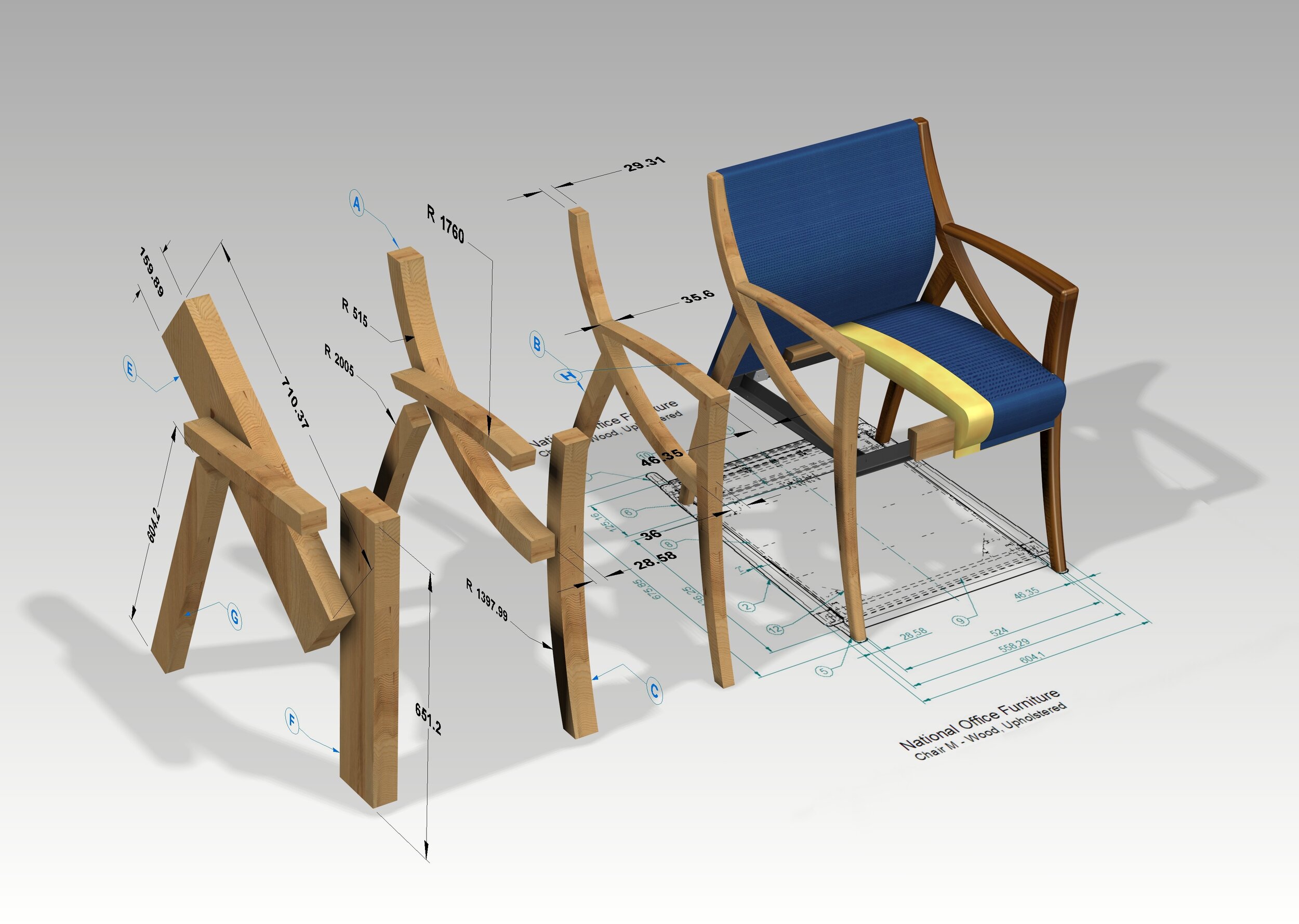

There are different ways to start: The obvious and best way is to start with your own 3D model (CAD or Poly). You can upload your files in our site. But that isn’t the only way. We can create a 3D CAD model from digital 2D drawings (DWG, DXF), from paper 2D drawings (PDF), or even from sketches and pictures (we may need additional data, like base dimensions, materials, and specific details). We can also create new 3D variations from existing models. We can make several renderings with different finishes, colors and textures.

HOW LONG DOES IT TAKE?

Small simple projects from your 3D models with existing materials/textures can be completed in 1 day. More complex models from your existing 3D models can take around 3 business days. Creating new 3D models or editing existing ones, prior to make the renderings require additional days based in the model complexity. If you need proprietary finishes/textures, we can create them, this may add additional days, specially if the approval process takes several interactions. We can give you a real estimation on your quote.

3D CAD MODELING OPTIONS

There are many choices to make that will help you get the most out of your money spent for 3D CAD services:

High/Low accuracy? Low accuracy parts take less time and saving you money.

Level of detail. Are there features that can be excluded?

File format. There are many possible output formats. (STEP, IGES, DWG, Solid Edge, SketchUp, Rhino, Solidworks, Revit, and more). To ensure that you receive the one that is compatible with your workflow, we can provide a test file in advance. Software specific format with feature tree and history? We can do it for a little extra cost.

Design-intent or as-built? All parts have manufacturing defects and errors, however small. Do you want to preserve these in the CAD model? (if is used just for display purposes), or create the model as the original designer intended? (If is used for manufacturing).

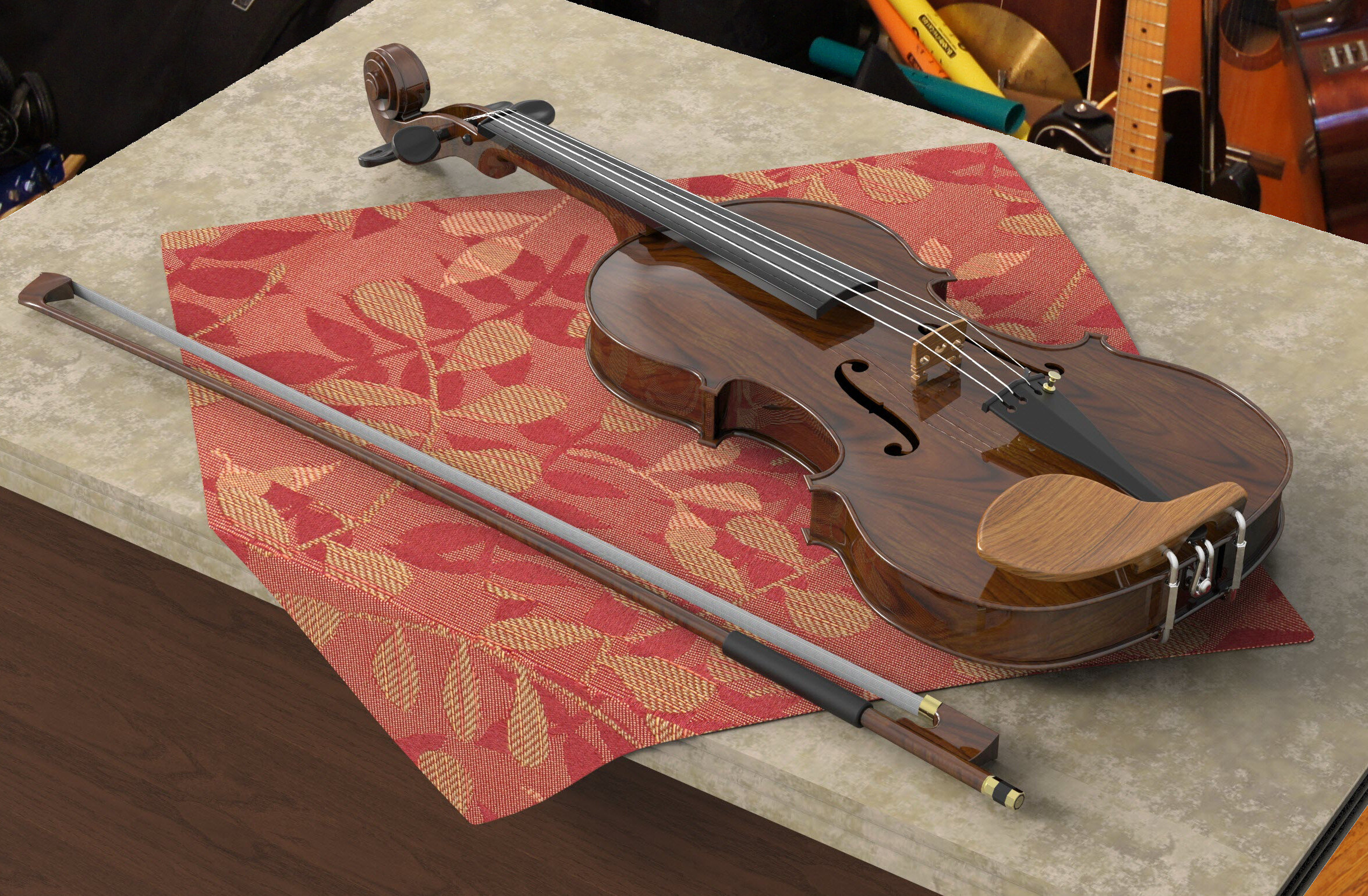

Meshed surfacing or geometry-based? For parts that are organic in nature or have a lot of compound curves, we can utilize Advance Surfacing modeling to create a NURBS models. For most manufacturing applications, a geometry-based model provides the clean model that you are need. For visualization only applications meshed surfaces are a better option.

Do you need an assembly file? This is a group of parts that are all modeled together. Are there multiple objects that need to be modeled to match? This is often the case with mating parts such as two halves of an enclosure.

Do you need 2D CAD drawings with dimensions? How much detail do you need?

Based on your requirements, we can recommend the best CAD modeling approach to achieve your goals in an economical way.

If you are able to do your own CAD and just need help, due to part complexity or resources constrains, we can do as much or as little as you need.

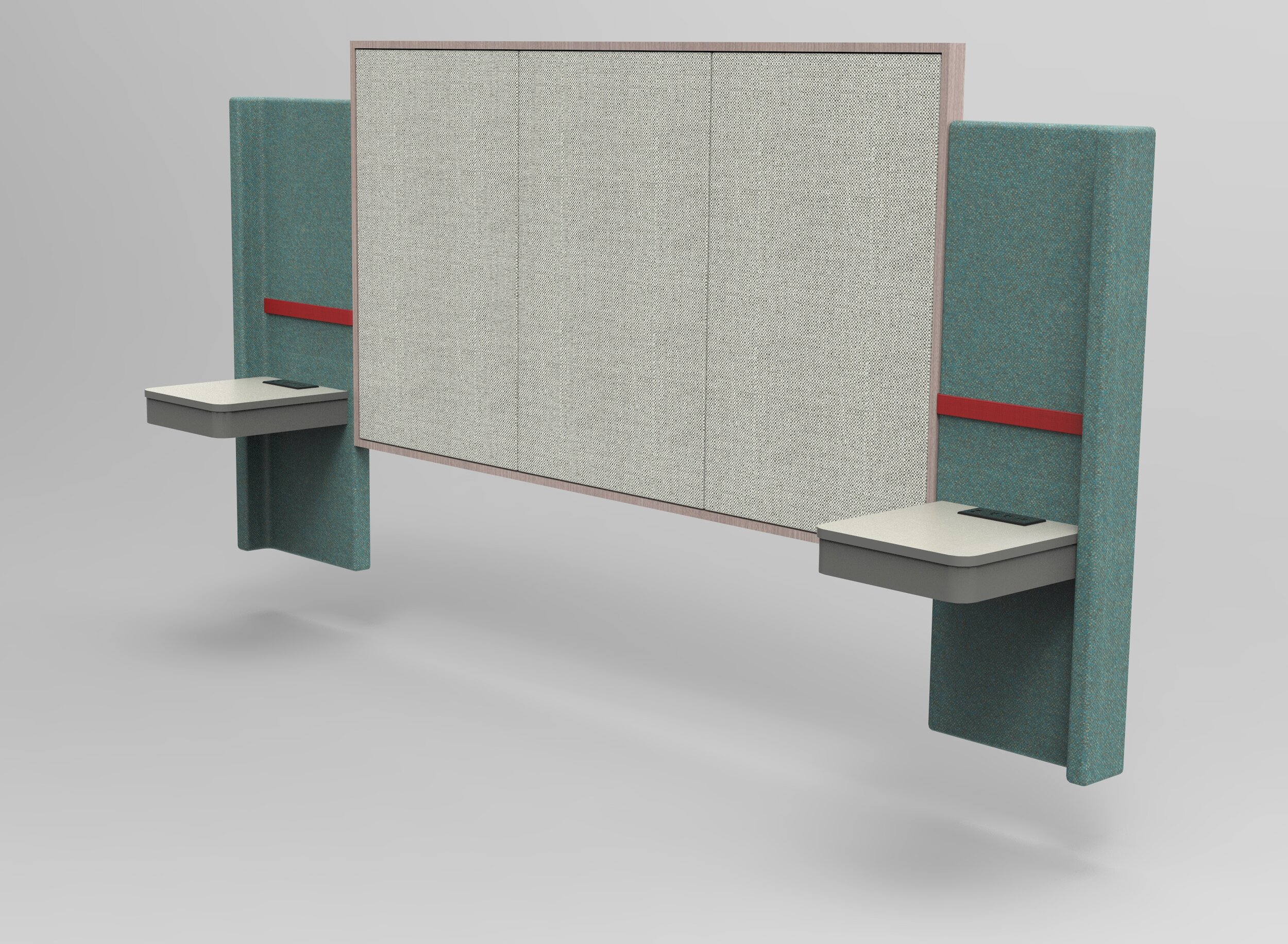

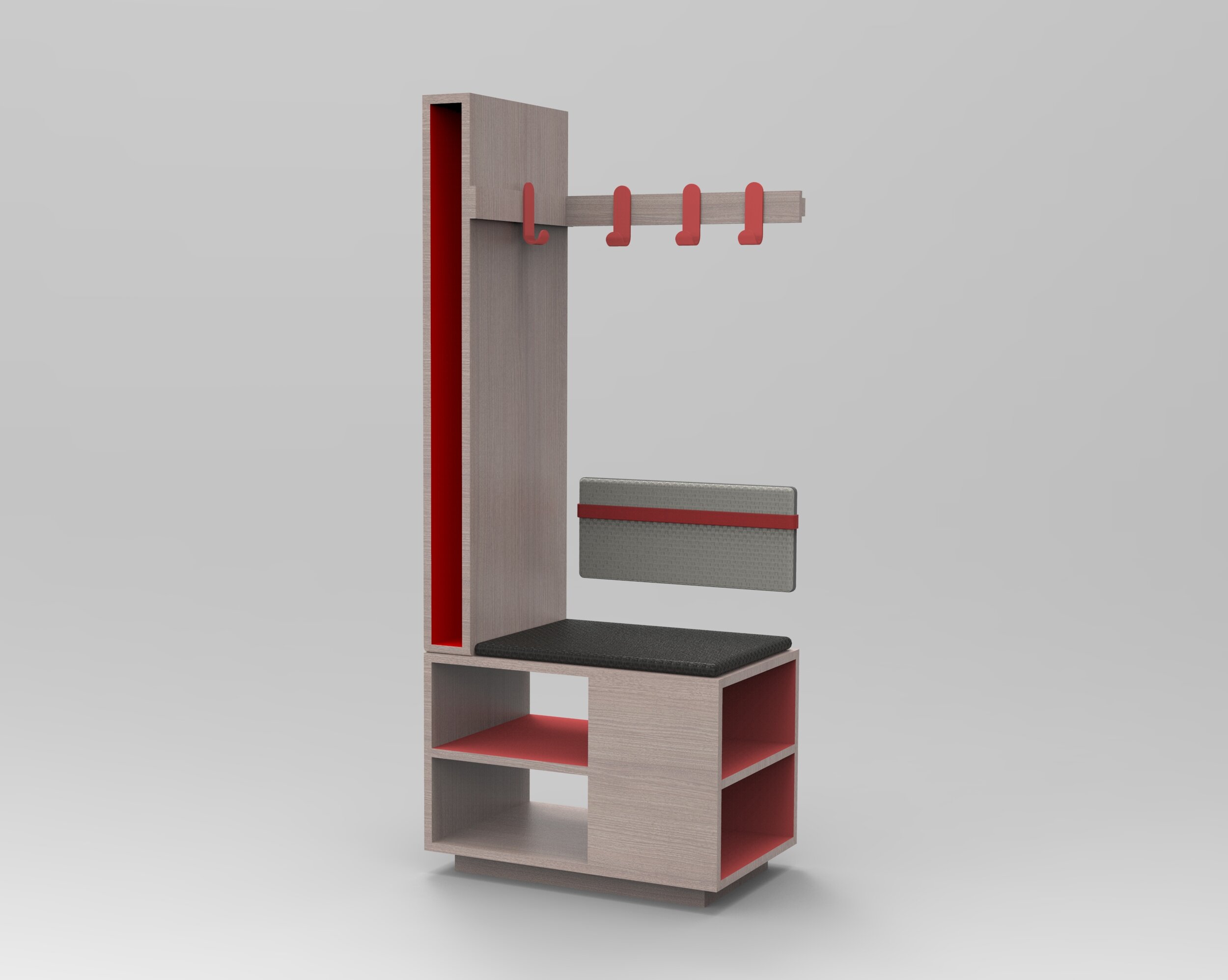

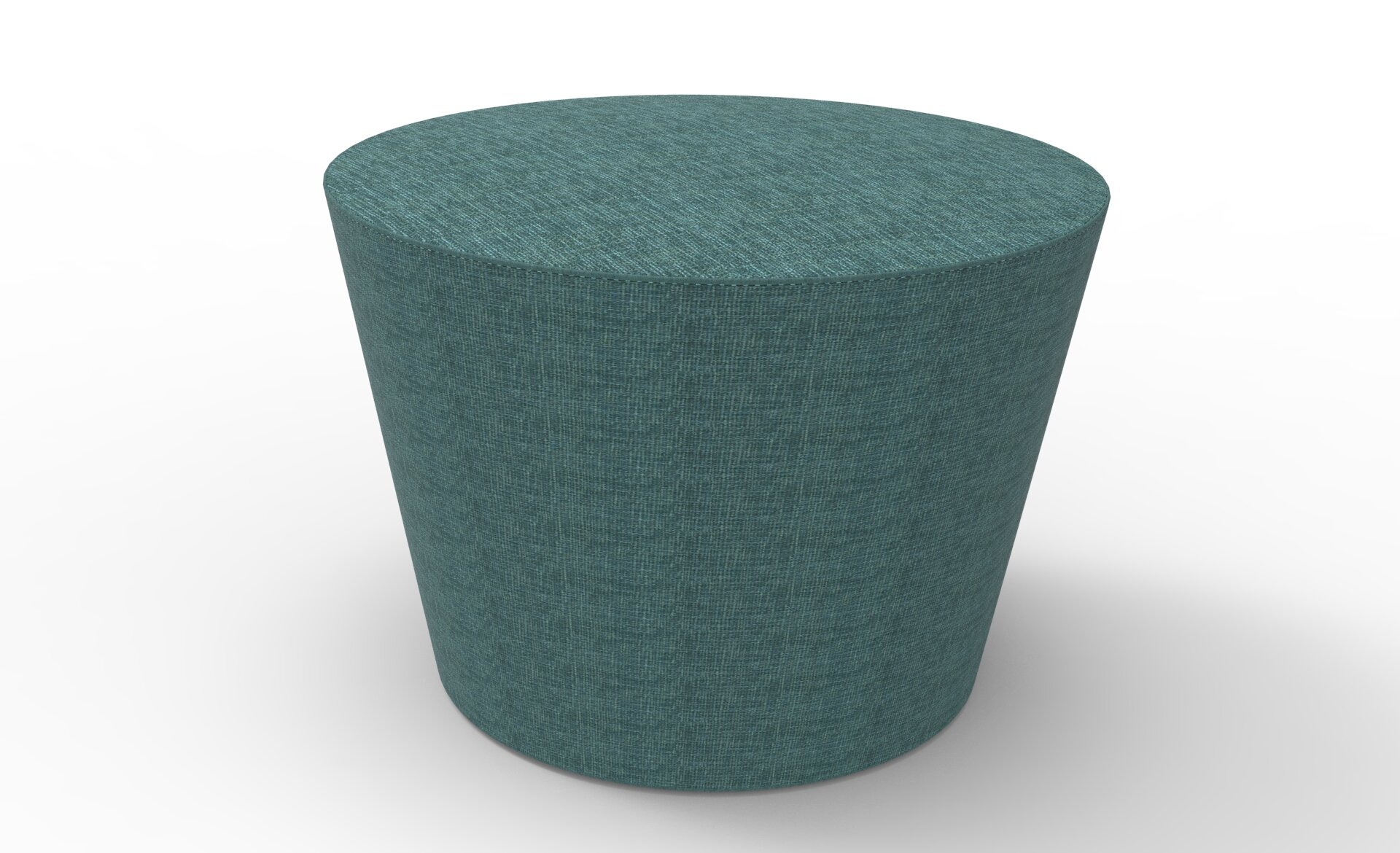

3D CAD SERVICES GALLERY

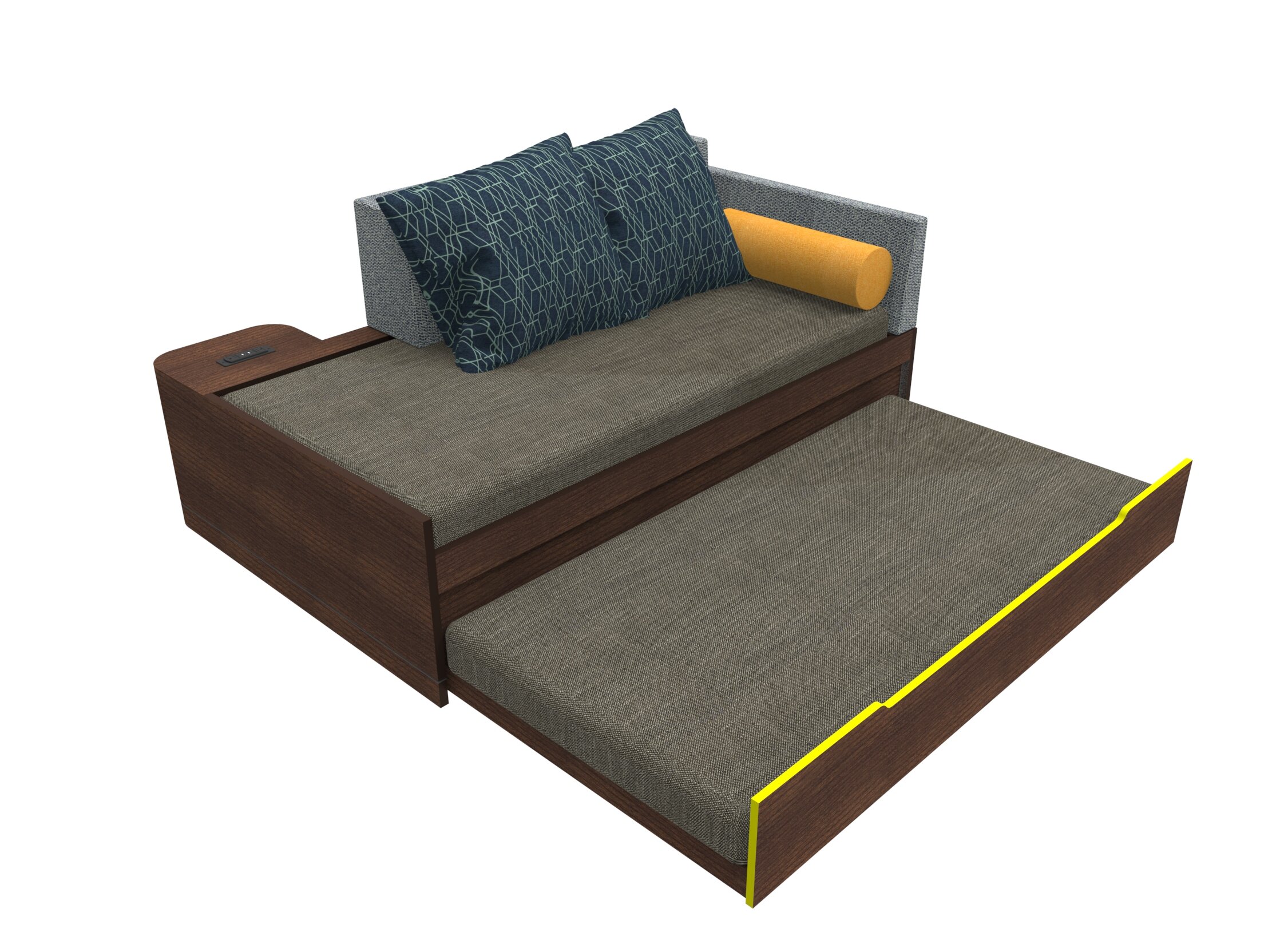

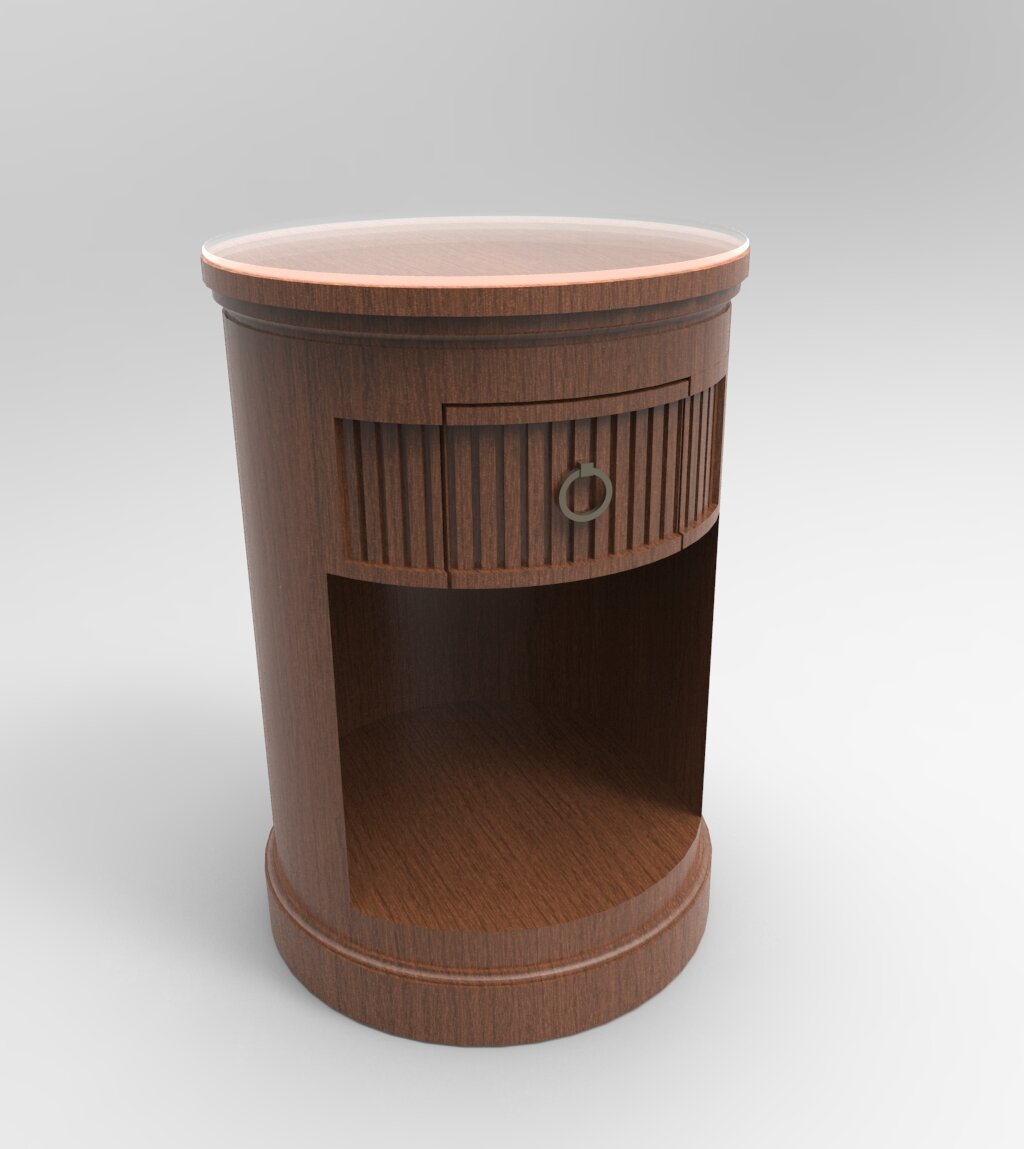

Here are some examples of CAD files we have created:

Design Intent

Design intent refers to a designer’s specifications of how a part should appear and function. The real manufactured part has some imperfections that are not shown in Design intent Cad parts.

Usually used in parametric modeling, design intent in CAD defines relationships between objects.

Deliverables will be shown as a "best fit". (ex. Parallel or perpendicular features will be 100% accurate). If the 3D model is used to produce 2D drawings, they will be cleaner and will allow for easier dimensioning.

The majority of clients that want the 3D model to build or manufacture it, want this option.

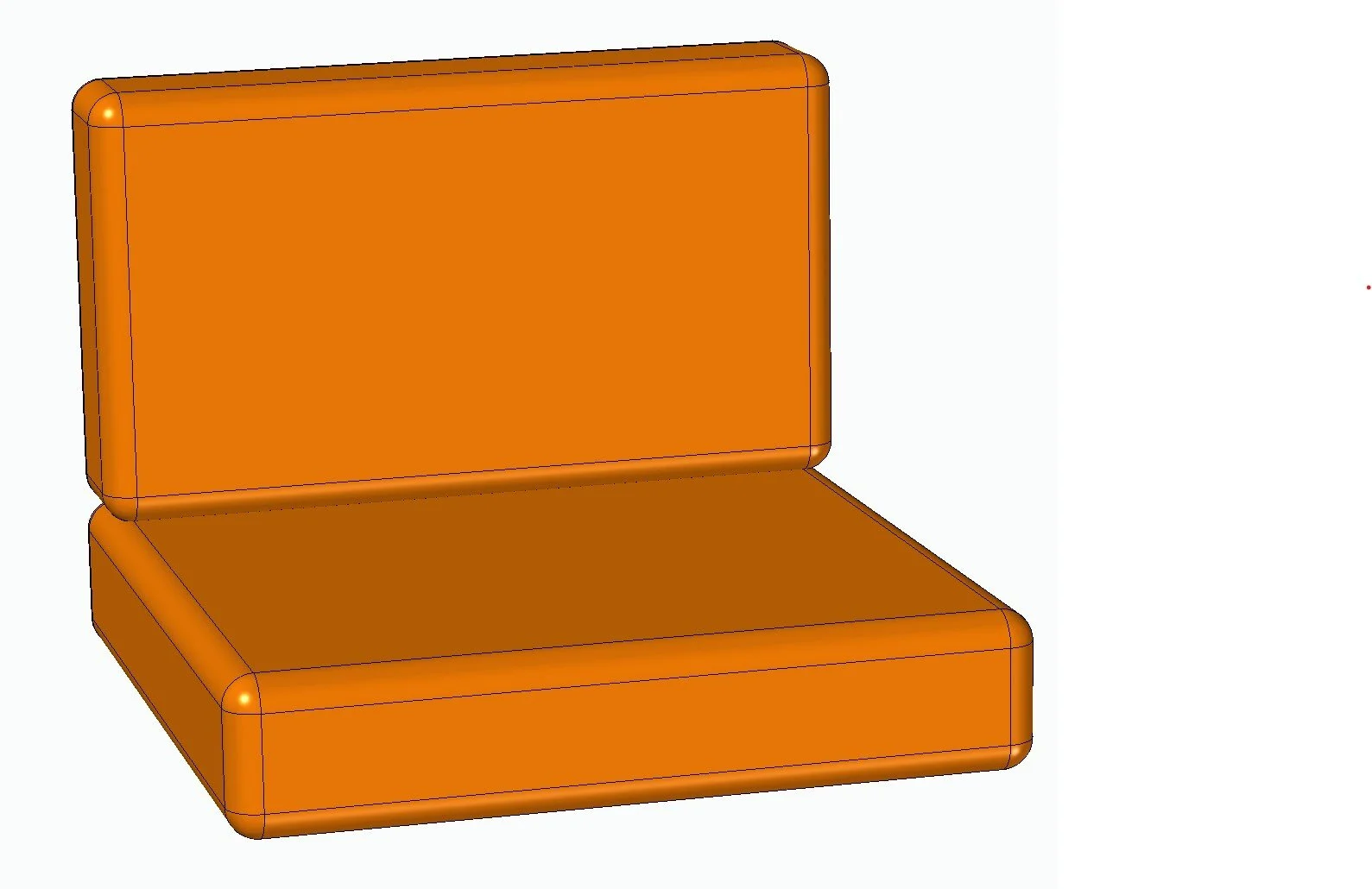

AS-BUILTS

Deliverables will be shown as close as possible to actual real part.

ex. Seams in cushions are going to be creased. This will produce reality-capture deliverables, but 2D drawings may show “crooked”. Dimensioning will not be as easy to read in 2D drawings.

Clients using the data for visualization only, and similar needs would require this option.